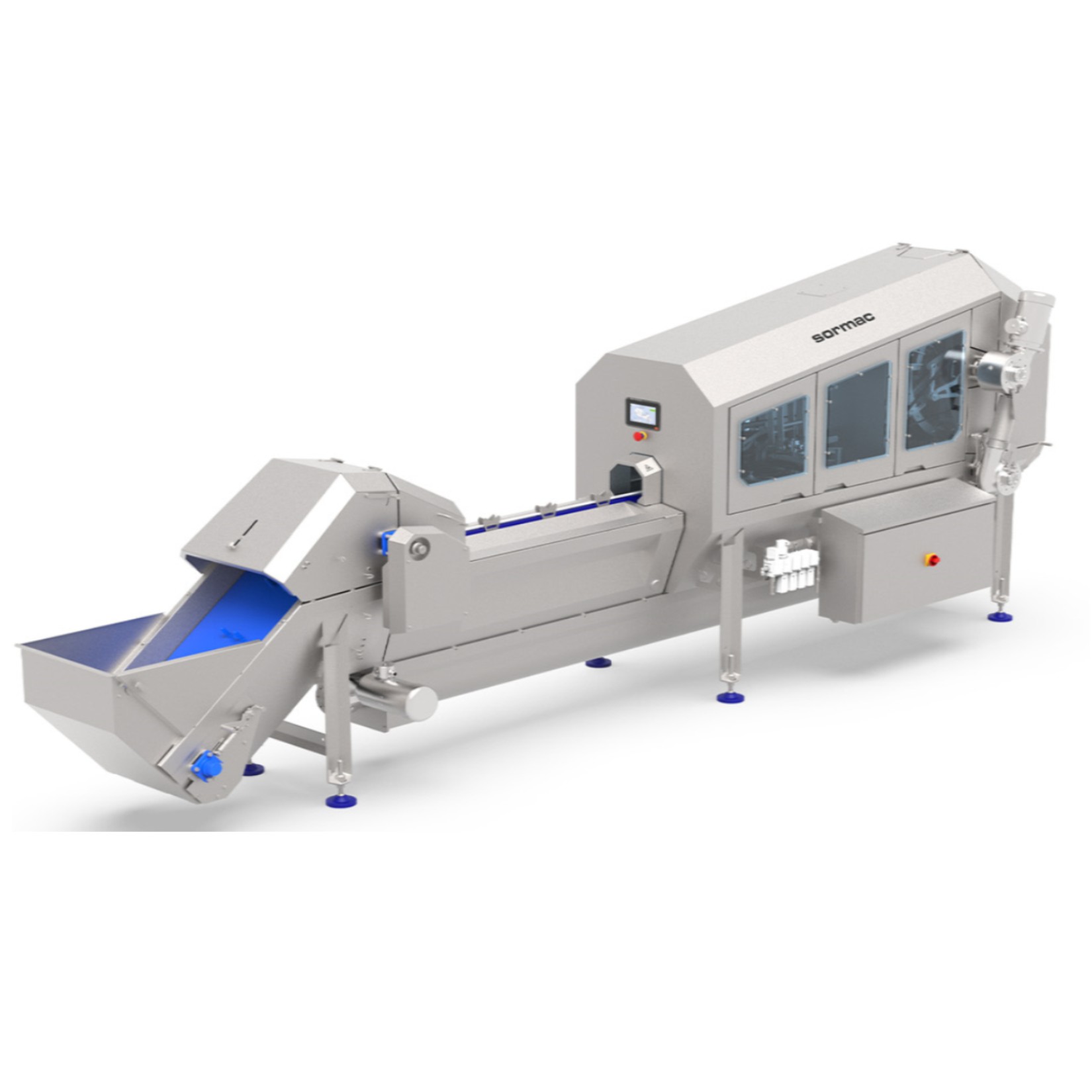

Onion Peeler – USM-H100

The USM-H100 onion peeler combines ease of use with a high level of reliability. The

Machine stands out most for its advanced, hygienic design. All motors,

for example, are made exclusively of stainless steel.

The operator has a control panel with all useful functions at his fingertips. In addition, all important information such as operator performance, the number of onions peeled and the causes of failure are visible.

The onions are taken from the hopper by means of a separation conveyor and placed on the holders of the belt conveyor.

The operator turns the onion into the right position. Then the onion is peeled by means of rotating knives and then cut into pieces at the front and back. Finally, the onion is collected and the peeling process begins. The onion is cut around the entire circumference and the skin is removed from the outside.

The Sormac air-saving technology used in the USM-H100 ensures low energy consumption combined with improved peeling quality.

| Model | USM-H100 (Sormac) |

| Capacity | 6000pcs/h |

| Product dimensions | Dia 60 - 140mm |

| Power requirements | 3Ph. / 400V / 50Hz / 2.05kW |

| Machine dimensions | 5770x1210x2190mm |