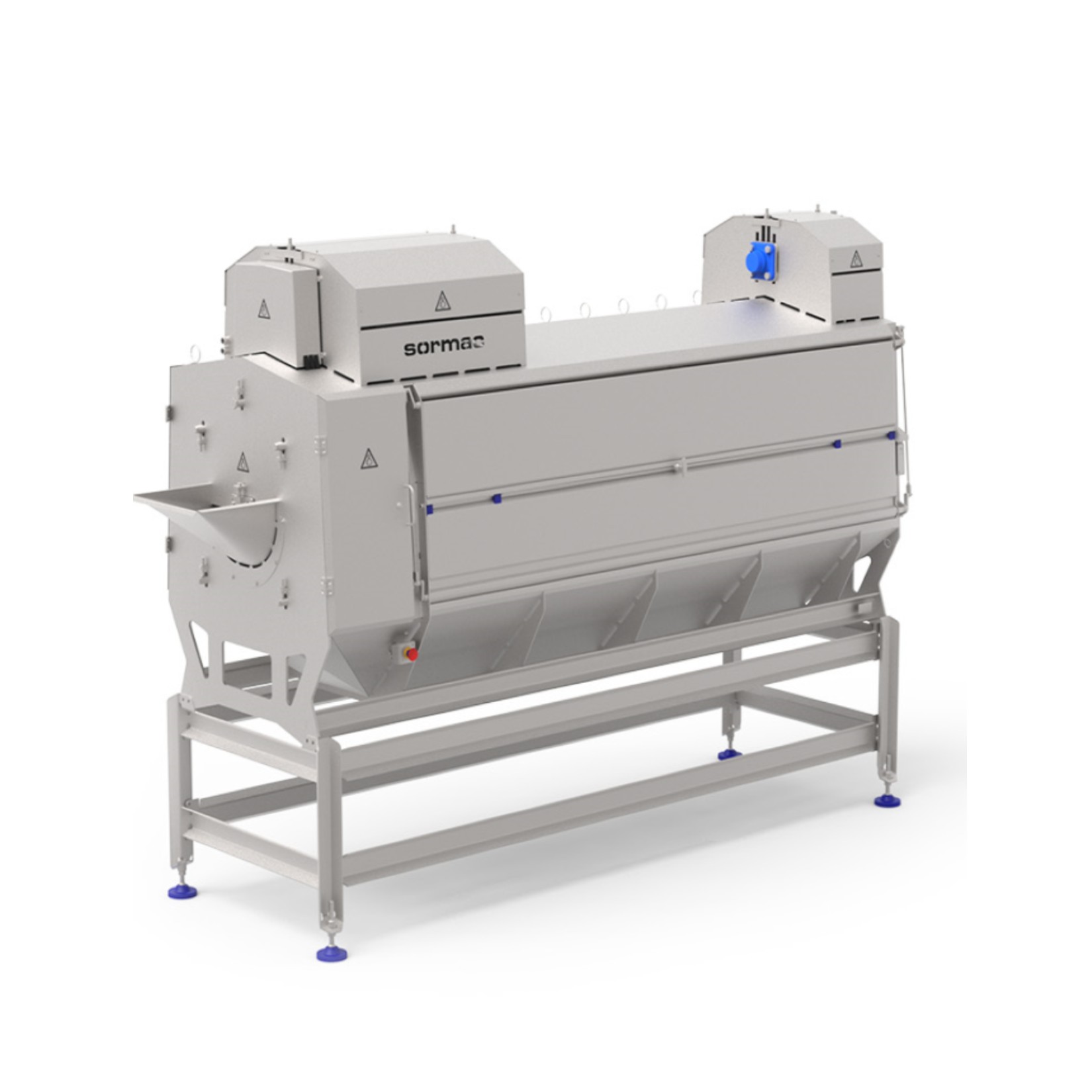

Revolver Peeler – CRR

The Sormac CRR revolver peeler has 25 carborundum (also known as silicon carbide) peeling rollers, which together form a drum. Both the drum and the rollers rotate separately and have independent speed control. Control is by means of a series of strong V-belts, which run on a drive pulley, ensuring very reliable operation.

Each roller has a double bearing arrangement and can be replaced very quickly thanks to a unique clamping device, which makes it unnecessary to dismantle the bearings. The high stability of the drum allows for very small distances between the rollers (< 4 mm).

Access to the internal cleaning of the peeler is provided by large side doors on both sides of the machine. On the right side of the machine are two integrated folding rollers for cleaning the conveyor screw and the inside of the drum.

The residence time in the peeler is controlled by a horizontal screw. On the outside of the rollers are two separate water spray systems, each of which can be controlled individually. If necessary, water can also be applied to the inside of the rollers via the screw shaft. The motors are built into a separate and hygienic chamber above the peeling area.

| Model | CRR |

| Capacity | 700kg/h |

| Product dimensions | Dia 5-45mm, Max Length 200mm |

| Power requirements | 6.5Kw |

| Machine dimensions | 4030x1270x2585mm |